Commercial Hard Candy Making Equipment Depositor Machine

Technical Specifications

| Exemplar | YGD50-80 | YGD150 | YGD300 | YGD450 | YGD600 |

| capacitas | 15-80kg/hr | 150kg/hr | 300kg/hr | 450kg/hr | 600kg/hr |

| Candy Pondus | sicut per Candy in magnitudine | ||||

| Volo deponendi | 20-50n/min | 55 65n/min | 55 65n/min | 55 65n/min | 55 65n/min |

| Vapor opus est | 250kg/h,0.5~0.8Mpa | 300kg/h,0.5~0.8Mpa | 400kg/h,0.5~0.8Mpa | 500kg/h,0.5~0.8Mpa | |

| Cogo aer postulationem | 0.2m³/min,0.4~0.6Mpa | 0.2m³/min,0.4~0.6Mpa | 0.25m³/min,0.4~0.6Mpa | 0.3m³/min,0.4~0.6Mpa | |

| Opus Condition | /Temperate:20~25℃;n/Humidity:55% | ||||

| Summa potentia | 6kw | 18Kw/380V | 27Kw/380V | 34Kw/380V | 38Kw/380V |

| Summa Longitudo | 1meter | 14m | 14m | 14m | 14m |

| Crassa Pondus | 300kg | 3500kg | 4000kg | 4500kg | 5000kg |

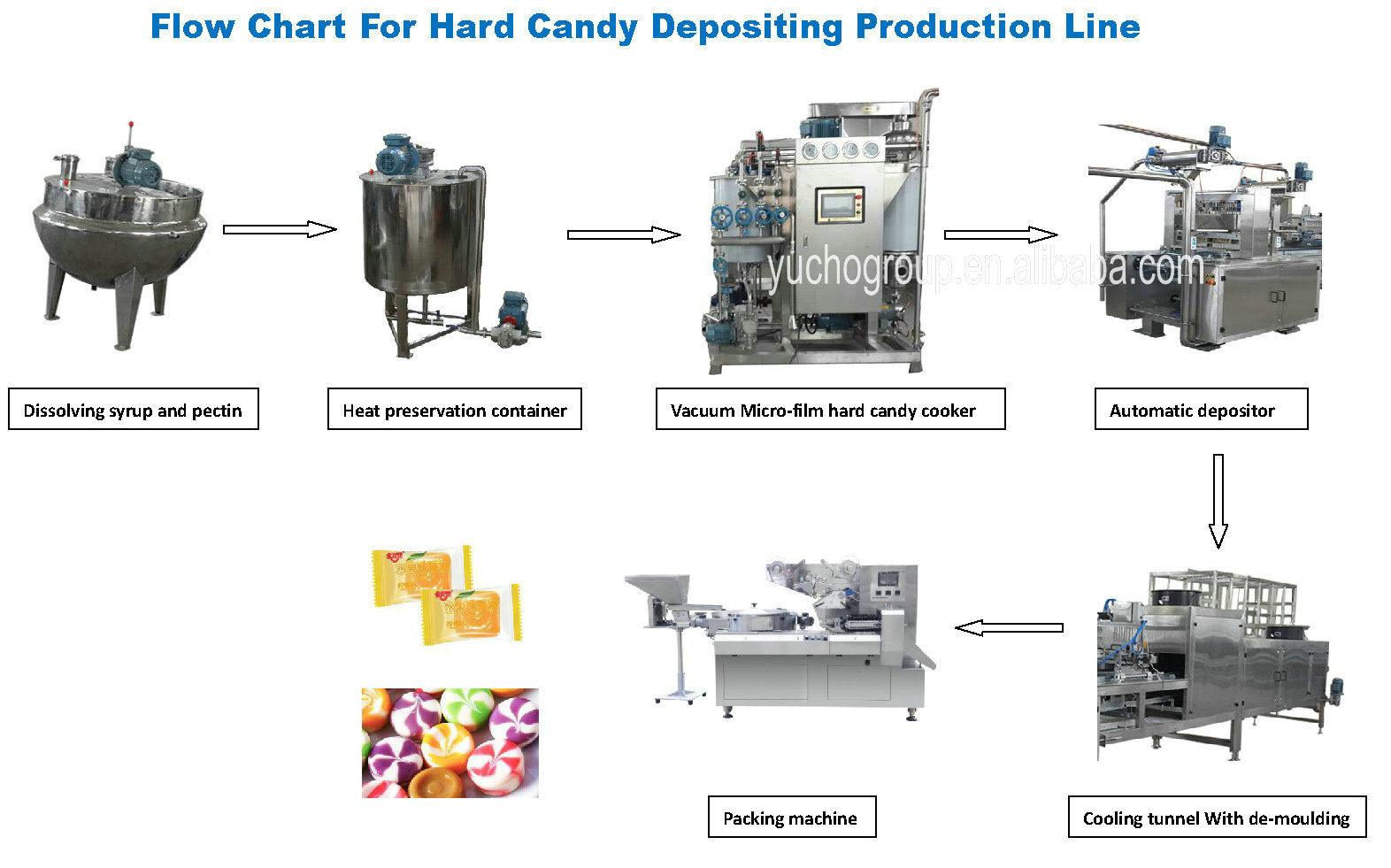

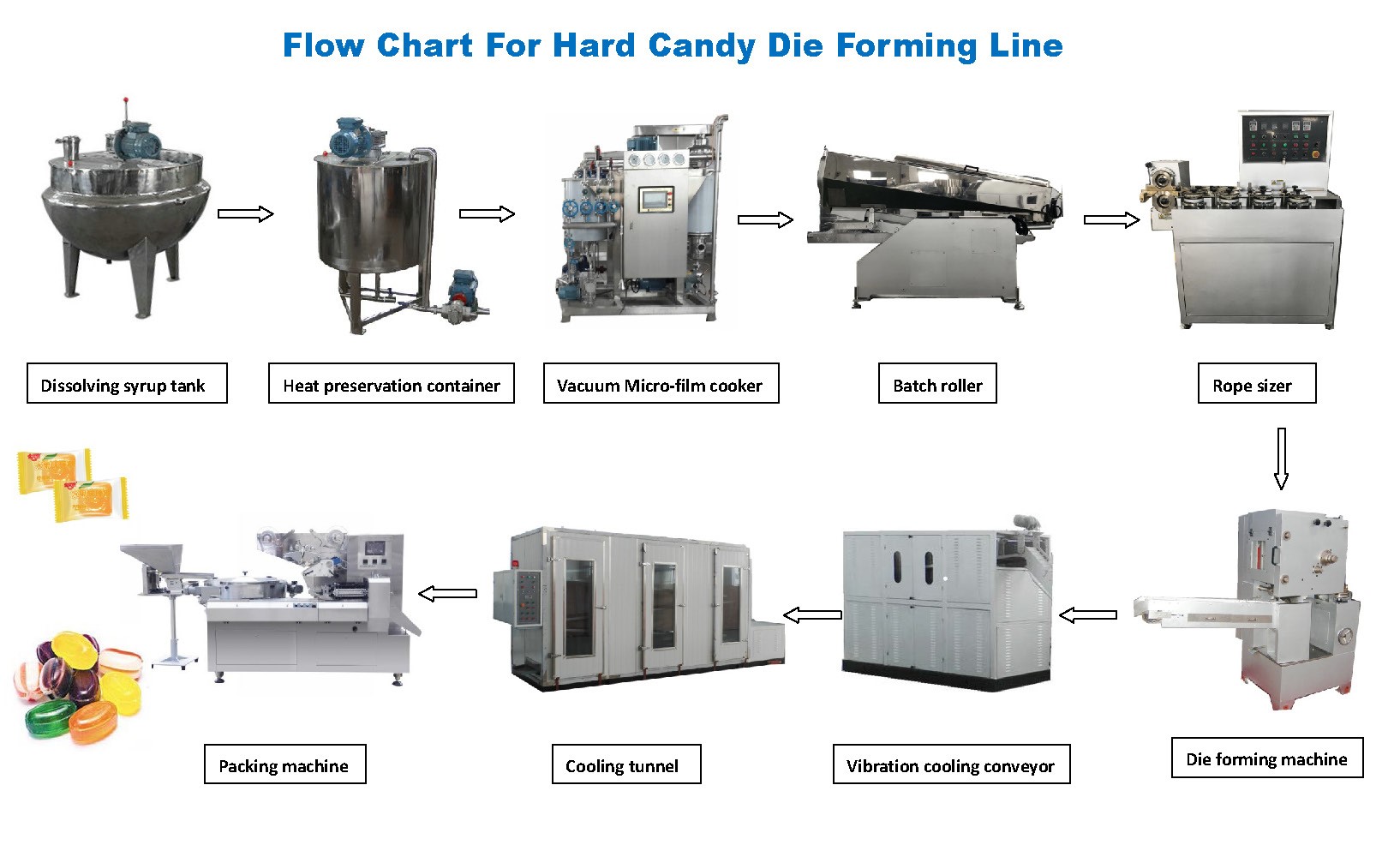

Commercial Ferreus Candy Faciens Equipment Depositum Machina est valde efficax fabrica ad Candy formandam. Centrum includit machinam implentem, funem maiusculum, lineum, pristinum, cuniculum refrigerans. These components are powered by a combination of machinery, electricity, and air to control center filling, lining, and forming, resulting in a well-designed, highly automated candy forming equipment.

Durum Candy linea productionis apta est ad lollipops informata irregularia producenda, ut: oblatum, ovatum, pedis magnus et viverra irregularis lollipops (figurae variae secundum exigentias Lorem).

Epistulam tuam hic scribe et mitte nobis